EuroAdsorbent offers a state-of-the-art sulfur recovery catalyst tailored for the Sulfur Recovery Unit (SRU), essential for mitigating air pollution and harnessing elemental sulfur for sulfuric acid production. Utilizing the renowned Claus process, our catalysts efficiently convert hydrogen sulfide and sulfur dioxide into elemental sulfur. While the Claus process typically recovers up to 98% of the hydrogen sulfide feedstream, EuroAdsorbent provides Tail Gas Treatment Units for comprehensive sulfur recovery, achieving rates of up to 99.5% or higher. Our product range includes Claus Catalyst + Tail Gas Treatment Catalyst and Super Claus + Tail Gas Treatment Catalyst, featuring high porosity activated alumina-based formulations fortified with Oxygen-sulfation Guard Catalysts and Titania Based Hydrolysis Catalysts for exceptional performance. Join EuroAdsorbent in revolutionizing sulfur management and advancing environmental compliance through innovative catalyst solutions.

Packing: 220-liter metallic drum (other packaging can be supplied on request).

Packing: 220-liter metallic drum (other packaging can be supplied on request).

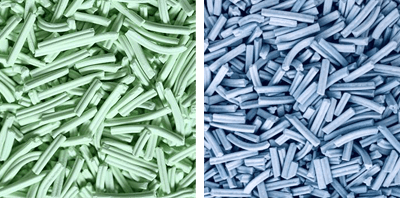

EA-SCA165

EA-SCA165 is a cutting-edge alumina Claus catalyst engineered for top-tier sulfur recovery performance in natural gas processing, oil refining, and petrochemical industries. Crafted with precision, EA-SCA165 boasts superior catalytic activity, effectively converting H2S/SO2, COS, and CS2 with unparalleled efficiency. Its spherical form maximizes surface area, ensuring optimal contact between reactants and catalyst for swift reactions. Designed for versatility, EA-SCA165 excels in both conventional Claus units and sub-dewpoint applications like MCRC, CBA, or Sulfreen. With its high macroporosity and exceptional thermal stability, EuroAdsorbent’s EA-SCA165 stands as the pinnacle of sulfur recovery catalysts, guaranteeing reliability and performance where it matters most.

Applications:

Oil Refineries

Gas Refineries

Petrochemicals

EA-SCA165

EA-SCA165 is a cutting-edge alumina Claus catalyst engineered for top-tier sulfur recovery performance in natural gas processing, oil refining, and petrochemical industries. Crafted with precision, EA-SCA165 boasts superior catalytic activity, effectively converting H2S/SO2, COS, and CS2 with unparalleled efficiency. Its spherical form maximizes surface area, ensuring optimal contact between reactants and catalyst for swift reactions. Designed for versatility, EA-SCA165 excels in both conventional Claus units and sub-dewpoint applications like MCRC, CBA, or Sulfreen. With its high macroporosity and exceptional thermal stability, EuroAdsorbent’s EA-SCA165 stands as the pinnacle of sulfur recovery catalysts, guaranteeing reliability and performance where it matters most.

Applications:

- Oil Refineries

- Gas Refineries

- Petrochemicals

EA-SCA315

EA-SCA315 is EuroAdsorbent’s groundbreaking sulfur recovery catalyst, engineered with advanced titanium oxide promotion for unparalleled performance in SRUs. Unlike conventional activated alumina catalysts, EA-SCA315 boasts exceptional COS and CS2 conversion rates, surpassing industry standards. Its innovative design enhances sulfur conversion efficiency, ensuring optimal purification of gas streams.

Crafted with cutting-edge materials, EA-SCA315 exhibits superior resistance to sulfation, prolonging catalyst lifespan and reducing operational costs. This catalyst represents a leap forward in SRU technology, offering enhanced reliability and productivity.

Applications:

Oil Refineries

Gas Refineries

Petrochemicals

EA-SCA315

EA-SCA315 is EuroAdsorbent’s groundbreaking sulfur recovery catalyst, engineered with advanced titanium oxide promotion for unparalleled performance in SRUs. Unlike conventional activated alumina catalysts, EA-SCA315 boasts exceptional COS and CS2 conversion rates, surpassing industry standards. Its innovative design enhances sulfur conversion efficiency, ensuring optimal purification of gas streams.

Crafted with cutting-edge materials, EA-SCA315 exhibits superior resistance to sulfation, prolonging catalyst lifespan and reducing operational costs. This catalyst represents a leap forward in SRU technology, offering enhanced reliability and productivity.

Applications:

- Oil Refineries

- Gas Refineries

- Petrochemicals

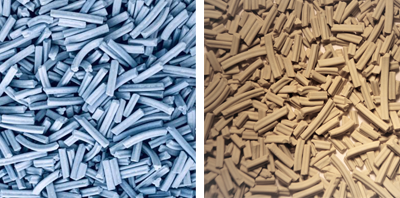

EA-SCT815

EA-SCT815 is a hydrolysis sulfur recovery catalyst that is crafted with precision and scientific expertise, it is a revolutionary extruded titanium dioxide catalyst, meticulously engineered for optimal performance in SRU.

At its core, EA-SCT815 is designed to efficiently hydrolyze carbonyl sulfide (COS) and carbon disulfide (CS2) into hydrogen sulfide (H2S), ensuring a remarkable 95-100% COS hydrolysis rate and 90-95% CS2 hydrolysis rate within a reaction temperature range of 280-340°C.

What sets EA-SCT815 apart is its unrivaled longevity and consistently high conversion rates. Through advanced manufacturing techniques and proprietary promoters, EA-SCT815 boasts superior resistance to sulfation and hydrothermal aging, ensuring prolonged service life without compromising performance.

Applications:

Oil Refineries

Gas Refineries

Petrochemicals

EA-SCT815

EA-SCT815 is a hydrolysis sulfur recovery catalyst that is crafted with precision and scientific expertise, it is a revolutionary extruded titanium dioxide catalyst, meticulously engineered for optimal performance in SRU.

At its core, EA-SCT815 is designed to efficiently hydrolyze carbonyl sulfide (COS) and carbon disulfide (CS2) into hydrogen sulfide (H2S), ensuring a remarkable 95-100% COS hydrolysis rate and 90-95% CS2 hydrolysis rate within a reaction temperature range of 280-340°C.

What sets EA-SCT815 apart is its unrivaled longevity and consistently high conversion rates. Through advanced manufacturing techniques and proprietary promoters, EA-SCT815 boasts superior resistance to sulfation and hydrothermal aging, ensuring prolonged service life without compromising performance.

Applications:

- Oil Refineries

- Gas Refineries

- Petrochemicals

EA-HCT750

EA-HCT750 is a tail gas hydrogenation catalyst, available in various shapes including spherical, trilobe, extrudate, and hollow ring configurations. This catalyst represents a breakthrough in industrial catalysis, offering unparalleled adaptability to meet diverse process requirements.

Each variant of EA-HCT750 maintains consistent high performance, leveraging a specialized formulation of cobalt and molybdenum on activated alumina support. Designed with precision engineering, these catalyst shapes ensure optimal surface area exposure and catalytic activity, enabling efficient conversion of sulfur compounds such as SO2, COS, CS2, and vapor sulfur elements.

Discover the versatility and technical excellence of EA-HCT750 from EuroAdsorbent, the catalyst solution designed to elevate tail gas hydrogenation processes to new levels of efficiency and sustainability.

Applications:

Oil Refineries

Gas Refineries

Petrochemicals

EA-HCT750

EA-HCT750 is a tail gas hydrogenation catalyst, available in various shapes including spherical, trilobe, extrudate, and hollow ring configurations. This catalyst represents a breakthrough in industrial catalysis, offering unparalleled adaptability to meet diverse process requirements.

Each variant of EA-HCT750 maintains consistent high performance, leveraging a specialized formulation of cobalt and molybdenum on activated alumina support. Designed with precision engineering, these catalyst shapes ensure optimal surface area exposure and catalytic activity, enabling efficient conversion of sulfur compounds such as SO2, COS, CS2, and vapor sulfur elements.

Discover the versatility and technical excellence of EA-HCT750 from EuroAdsorbent, the catalyst solution designed to elevate tail gas hydrogenation processes to new levels of efficiency and sustainability.

Applications:

- Oil Refineries

- Gas Refineries

- Petrochemicals

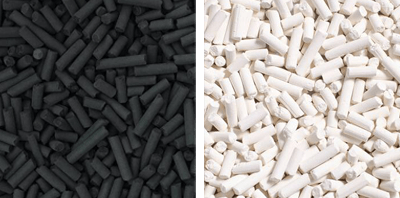

EA-SCI315

EA-SCI315, an innovative sulfur recovery catalyst designed for optimum performance in Claus reactors. Engineered with precision, EA-SCI315 features iron-promoted activated alumina, ensuring unparalleled efficiency in oxygen removal from the inlet process gas. Acting as a safeguard, EA-SCI315 shields Claus catalysts from sulfate formation, prolonging their lifespan and enhancing overall operational integrity. Strategically placed in the 2nd and 3rd reactors, this catalyst is a cornerstone in sulfur recovery processes, guaranteeing consistent and reliable results. Trust EuroAdsorbent’s EA-SCI315 to streamline your operations, minimize downtime, and maximize productivity in sulfur recovery applications.

Applications:

Oil Refineries

Gas Refineries

Petrochemicals

EA-SCI315

EA-SCI315, an innovative sulfur recovery catalyst designed for optimum performance in Claus reactors. Engineered with precision, EA-SCI315 features iron-promoted activated alumina, ensuring unparalleled efficiency in oxygen removal from the inlet process gas. Acting as a safeguard, EA-SCI315 shields Claus catalysts from sulfate formation, prolonging their lifespan and enhancing overall operational integrity. Strategically placed in the 2nd and 3rd reactors, this catalyst is a cornerstone in sulfur recovery processes, guaranteeing consistent and reliable results. Trust EuroAdsorbent’s EA-SCI315 to streamline your operations, minimize downtime, and maximize productivity in sulfur recovery applications.

Applications:

- Oil Refineries

- Gas Refineries

- Petrochemicals