EuroAdsorbent specializes in advanced hydrotreating catalysts, crucial for purifying liquid petroleum fractions by eliminating up to 97% of contaminants including sulfur, nitrogen, oxygen, and metals. Our catalysts ensure superior quality and performance, safeguarding equipment and enhancing final product standards. Leveraging cutting-edge hydrotreating, or hydrodesulfurization, techniques, our catalysts efficiently convert organic sulfur, nitrogen, and oxygen compounds into hydrocarbons and benign byproducts. Employing alumina as a carrier with metal oxide impregnation such as NiMo, CoMo, and NiCoMo, our catalysts deliver exceptional results across various refining processes including Naptha, Diesel, and VGO. EuroAdsorbent’s solutions guarantee optimal performance with minimal energy consumption, meeting stringent emission standards.

Packing: 220-liter metallic drum (other packaging can be supplied on request).

Packing: 220-liter metallic drum (other packaging can be supplied on request).

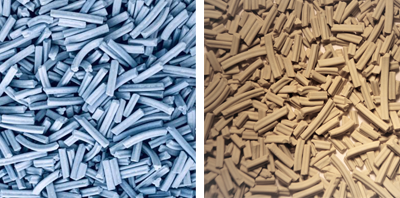

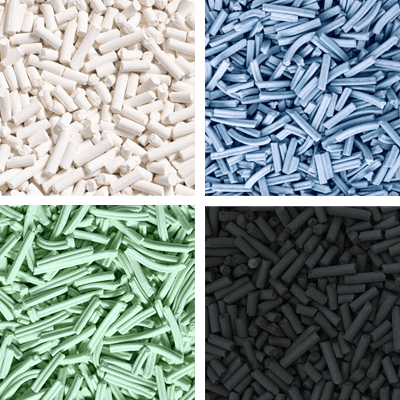

EA-HCN820

EA-HCN820 is a speciallized NiMo Naptha Hydrotreating Catalyst meticulously crafted for top-tier performance. Engineered with advanced denitrification, olefin hydrogenation, and desulfurization capabilities, EA-HCN820 stands as a pinnacle in catalyst innovation. Developed to excel in diverse applications including cracked Naphtha processing, olefin saturation reactors, and first stage HDN/HDM of hydrocracker and FCC pretreatment, this catalyst delivers unmatched efficiency.

Applications:

Naphtha hydrotreating

FCC pretreatment

EA-HCN820

EA-HCN820 is a speciallized NiMo Naptha Hydrotreating Catalyst meticulously crafted for top-tier performance. Engineered with advanced denitrification, olefin hydrogenation, and desulfurization capabilities, EA-HCN820 stands as a pinnacle in catalyst innovation. Developed to excel in diverse applications including cracked Naphtha processing, olefin saturation reactors, and first stage HDN/HDM of hydrocracker and FCC pretreatment, this catalyst delivers unmatched efficiency.

Applications:

- Naphtha hydrotreating

- FCC pretreatment

EA-HCN875

Introducing EA-HCN870, the epitome of catalyst excellence from EuroAdsorbent. Engineered for top-tier performance in naptha hydrotreating, it showcases unparalleled hydrodenitrogenation (HDN) and hydrodesulfurization (HDS) activity. This catalyst ensures optimal conversion of heavy hydrocarbons into lighter, more valuable products, enhancing product density and yield. Its stability under extreme conditions guarantees consistent results in both straight-run and cracked distillate fractions. Studies confirm its unmatched effectiveness in nitrogen-rich feedstocks, making it the preferred choice for naphtha and kerosene hydrotreaters in FCC and coker fractions.

Applications:

Naphtha/Kerosene hydrotreating

FCC pretreatment

Diesel hydrotreating

Mild hydrocracking

Lube polishing

EA-HCN875

Introducing EA-HCN870, the epitome of catalyst excellence from EuroAdsorbent. Engineered for top-tier performance in naptha hydrotreating, it showcases unparalleled hydrodenitrogenation (HDN) and hydrodesulfurization (HDS) activity. This catalyst ensures optimal conversion of heavy hydrocarbons into lighter, more valuable products, enhancing product density and yield. Its stability under extreme conditions guarantees consistent results in both straight-run and cracked distillate fractions. Studies confirm its unmatched effectiveness in nitrogen-rich feedstocks, making it the preferred choice for naphtha and kerosene hydrotreaters in FCC and coker fractions.

Appliccations:

- Naphtha/Kerosene hydrotreating

- FCC pretreatment

- Diesel hydrotreating

- Mild hydrocracking

- Lube polishing

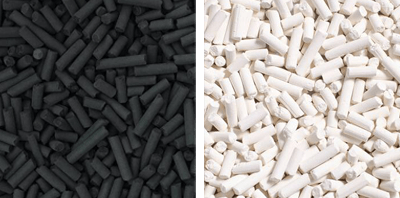

EA-SCC730

Introducing EA-HCC730, EuroAdsorbent’s latest hydrotreating catalyst tailored for fluid catalytic cracking (FCC) gasoline post-treatment. Designed with a CoMo type composition, EA-HCC730 ensures optimal hydrodesulfurization (HDS) activity while minimizing octane loss, essential for achieving Ultra Low Sulfur Gasoline (ULSG). Its robust formulation exhibits exceptional tolerance to metal poisoning, ensuring reliable sulfur removal without compromising octane numbers. As a part of EuroAdsorbent’s established catalyst lineup, EA-HCC730 promises dependable performance for stable, flexible, and profitable gasoline production. Applied in FCC gasoline post-treatment, it upholds the industry standard for catalyst efficiency, contributing to sustainable refining practices.

Applications:

Oil Refineries

Gas Refineries

Petrochemicals

EA-SCC730

Introducing EA-HCC730, EuroAdsorbent’s latest hydrotreating catalyst tailored for fluid catalytic cracking (FCC) gasoline post-treatment. Designed with a CoMo type composition, EA-HCC730 ensures optimal hydrodesulfurization (HDS) activity while minimizing octane loss, essential for achieving Ultra Low Sulfur Gasoline (ULSG). Its robust formulation exhibits exceptional tolerance to metal poisoning, ensuring reliable sulfur removal without compromising octane numbers. As a part of EuroAdsorbent’s established catalyst lineup, EA-HCC730 promises dependable performance for stable, flexible, and profitable gasoline production. Applied in FCC gasoline post-treatment, it upholds the industry standard for catalyst efficiency, contributing to sustainable refining practices.

Applications:

- Oil Refineries

- Gas Refineries

- Petrochemicals

EA-HCT750

EA-HCT750 is a tail gas hydrogenation catalyst, available in various shapes including spherical, trilobe, extrudate, and hollow ring configurations. This catalyst represents a breakthrough in industrial catalysis, offering unparalleled adaptability to meet diverse process requirements.

Each variant of EA-HCT750 maintains consistent high performance, leveraging a specialized formulation of cobalt and molybdenum on activated alumina support. Designed with precision engineering, these catalyst shapes ensure optimal surface area exposure and catalytic activity, enabling efficient conversion of sulfur compounds such as SO2, COS, CS2, and vapor sulfur elements.

Discover the versatility and technical excellence of EA-HCT750 from EuroAdsorbent, the catalyst solution designed to elevate tail gas hydrogenation processes to new levels of efficiency and sustainability.

Applications:

It is applied in Fluid Catalytic Cracking (FCC) gasoline post-treatment.

EA-HCT750

EA-HCT750 is a tail gas hydrogenation catalyst, available in various shapes including spherical, trilobe, extrudate, and hollow ring configurations. This catalyst represents a breakthrough in industrial catalysis, offering unparalleled adaptability to meet diverse process requirements.

Each variant of EA-HCT750 maintains consistent high performance, leveraging a specialized formulation of cobalt and molybdenum on activated alumina support. Designed with precision engineering, these catalyst shapes ensure optimal surface area exposure and catalytic activity, enabling efficient conversion of sulfur compounds such as SO2, COS, CS2, and vapor sulfur elements.

Discover the versatility and technical excellence of EA-HCT750 from EuroAdsorbent, the catalyst solution designed to elevate tail gas hydrogenation processes to new levels of efficiency and sustainability.

Applications:

- It is applied in Fluid Catalytic Cracking (FCC) gasoline post-treatment.