Carbon molecular sieve (CMS) is a specialized material akin to zeolite, featuring precise pore sizes ideal for gas separation. Created through the pyrolysis of organic sources like polymers or biomass, CMS can be fashioned into membranes of various structures. CMS has been pivotal in commercializing pressure swing adsorption for nitrogen-air separation. Unlike activated carbon, CMS boasts a narrower pore size distribution, typically between 3 – 5 Å, offering heightened selectivity. Determining CMS micropore size distribution often involves molecular probe methods.

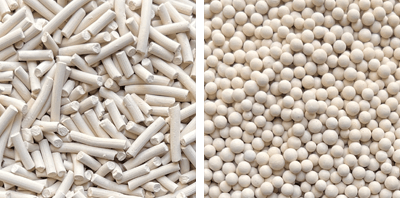

Adapting to the unique specifications of individual units and accommodating customer preferences, we offer flexibility in the supply of this product in various sizes, ranging from 0.8 to 2.2 mm.

Packing: 20 KG/Plastic Drum, 40 KG/Plastic Drum (other packaging can be supplied on request).

Adapting to the unique specifications of individual units and accommodating customer preferences, we offer flexibility in the supply of this product in various sizes, ranging from 0.8 to 2.2 mm.

Packing: 20 KG/Plastic Drum, 40 KG/Plastic Drum (other packaging can be supplied on request).

EA-CMS Series

EA-CMS Series, a groundbreaking solution for nitrogen generation leveraging Carbon Molecular Sieve technology. Engineered with a vast porous structure, our CMS maximizes surface area, optimizing the adsorption process essential for PSA. By exploiting the selective affinity of CMS towards oxygen molecules, our series efficiently separates nitrogen from compressed air, achieving purity levels of up to 99.999%. With countless 4 angstrom pores, our CMS ensures precise gas separation, delivering unparalleled nitrogen yield capacity and recovery rates.

Moreover, its durability, minimal ash content, and uniform particles guarantee longevity and optimal performance. Experience cost-effectiveness and reliability with our rigorously tested, high-quality CMS products, suitable for a variety of industrial applications such as petroleum, metal heat treatment, electronics, and food preservation.

Applications:

Industrial PSA Nitrogn generators

EA-CMS Series

EA-CMS Series, a groundbreaking solution for nitrogen generation leveraging Carbon Molecular Sieve technology. Engineered with a vast porous structure, our CMS maximizes surface area, optimizing the adsorption process essential for PSA. By exploiting the selective affinity of CMS towards oxygen molecules, our series efficiently separates nitrogen from compressed air, achieving purity levels of up to 99.999%. With countless 4 angstrom pores, our CMS ensures precise gas separation, delivering unparalleled nitrogen yield capacity and recovery rates.

Moreover, its durability, minimal ash content, and uniform particles guarantee longevity and optimal performance. Experience cost-effectiveness and reliability with our rigorously tested, high-quality CMS products, suitable for a variety of industrial applications such as petroleum, metal heat treatment, electronics, and food preservation.

Applications:

- Industrial PSA Nitrogn generators