The EA-SR series represents a pinnacle in sulfur removal adsorbent, designed to address the critical need for high-purity feed gases and liquids in industrial processes. These specialty adsorbents utilize advanced chemical mechanisms to selectively capture sulfur compounds from diverse streams, including various oil refinery’s hydrocarbon cuts and purification units for hydrogen, oxygen, ethylene, propylene, and PDH. By targeting sulfur contaminants, EA-SR products prevent downstream issues such as corrosion, pressure drops, and catalyst poisoning, ensuring optimal system performance and product quality. Employing a combination of physical and chemical separation techniques, the SR series stands as an intelligent and efficient solution, delivering unparalleled purity and environmental sustainability to industrial processes.

Packing: 220-liter metallic drum (other packaging can be supplied on request).

Packing: 220-liter metallic drum (other packaging can be supplied on request).

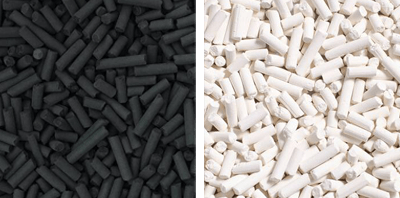

EA-SRA950

EA-SRA950 is a promoted alumina-based sulfur removal adsorbent engineered with precision, this high-performance spherical catalyst is a breakthrough in sulfur removal technology. Drawing from the success of our renowned alumina catalysts, the EA-SRA950 boasts unparalleled efficiency in removing sulfur compounds, particularly carbonyl sulfide (COS).

Designed with a focus on scientific excellence, our catalyst ensures optimal conversion of COS to hydrogen sulfide and carbon dioxide, even at low temperatures. Its superior activity guarantees maximum efficiency in COS hydrolysis reactions, making it indispensable in various industrial processes. Partnering seamlessly with ZnO desulfurization catalysts, it achieves impeccable desulfurization in propylene, syngas, CO2 gas, and liquid hydrocarbon plants.

Applications:

Propylene purification

Syngas purification

Purification of liquid hydrocarbons

EA-SRA950

EA-SRA950 is a promoted alumina-based sulfur removal adsorbent engineered with precision, this high-performance spherical catalyst is a breakthrough in sulfur removal technology. Drawing from the success of our renowned alumina catalysts, the EA-SRA950 boasts unparalleled efficiency in removing sulfur compounds, particularly carbonyl sulfide (COS).

Designed with a focus on scientific excellence, our catalyst ensures optimal conversion of COS to hydrogen sulfide and carbon dioxide, even at low temperatures. Its superior activity guarantees maximum efficiency in COS hydrolysis reactions, making it indispensable in various industrial processes. Partnering seamlessly with ZnO desulfurization catalysts, it achieves impeccable desulfurization in propylene, syngas, CO2 gas, and liquid hydrocarbon plants.

Applications:

- Propylene purification

- Syngas purification

- Purification of liquid hydrocarbons

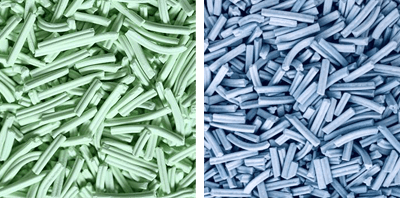

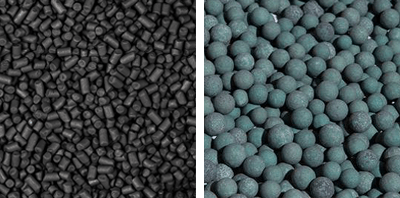

EA-SRM750

EA-SRM750 boasts a MnO-based formulation meticulously designed for sulfur removal adsorbent, excelling in eliminating H2S, RSH, and COS contaminants. Harnessing the power of hydrogen, EA-SRM750 facilitates the hydrolysis of COS and RSH into H2S, effectively neutralizing them with MnO. Available in both oxidized and reduced forms, this versatile solution ensures optimized performance across diverse applications, including platformer recycle gas, reformer sulfur guard, LPG, NHT, natural gas, and various hydrocarbon purification processes.

Applications:

Purification of various oil refinery process streams like Naphtha, LPG, Reforming, Recycle Gas, etc.

EA-SRM750

EA-SRM750 boasts a MnO-based formulation meticulously designed for sulfur removal adsorbent, excelling in eliminating H2S, RSH, and COS contaminants. Harnessing the power of hydrogen, EA-SRM750 facilitates the hydrolysis of COS and RSH into H2S, effectively neutralizing them with MnO. Available in both oxidized and reduced forms, this versatile solution ensures optimized performance across diverse applications, including platformer recycle gas, reformer sulfur guard, LPG, NHT, natural gas, and various hydrocarbon purification processes.

Applications:

- Purification of various oil refinery process streams like Naphtha, LPG, Reforming, Recycle Gas, etc.

EA-SRZ900

EA-SRZ900 is a zinc oxide sulfur removal adsorbent that is engineered for feedstock purification in hydrogen, ammonia, and organic chemical production, it swiftly eliminates hydrogen sulfide, achieving levels below 0.1ppm.

Exceptionally versatile, EA-SRZ900 thrives in harsh conditions, boasting unparalleled sulfur absorption capacity, activity, and strength. Its durability ensures sustained performance, even in environments with high steam/gas ratios. Operating optimally from 200℃ to 400℃, it efficiently converts and absorbs organic sulfur compounds like COS and CS2. Available in both extrudate and spherical forms, EA-SRZ900 promises unmatched efficacy tailored to your specific needs.

Applications:

Purification of hydrocarbon feed streams

Hydrogen Purification

EA-SRZ900

EA-SRZ900 is a zinc oxide sulfur removal adsorbent that is engineered for feedstock purification in hydrogen, ammonia, and organic chemical production, it swiftly eliminates hydrogen sulfide, achieving levels below 0.1ppm.

Exceptionally versatile, EA-SRZ900 thrives in harsh conditions, boasting unparalleled sulfur absorption capacity, activity, and strength. Its durability ensures sustained performance, even in environments with high steam/gas ratios. Operating optimally from 200℃ to 400℃, it efficiently converts and absorbs organic sulfur compounds like COS and CS2. Available in both extrudate and spherical forms, EA-SRZ900 promises unmatched efficacy tailored to your specific needs.

Applications:

- Purification of hydrocarbon feed streams

- Hydrogen Purification

EA-SRM120

EA-SRM120 is a mixed metal oxide sulfur removal adsorbent for unparalleled efficiency in eliminating hydrogen sulfide (H2S), arsine (AsH3), phosphine (PH3), carbonyl sulfide (COS), and mercaptans from liquid and vapor streams. Engineered with precision, EA-SRM120 excels in purifying natural gas, LNG, naphtha, propylene, propane, LPG, and various hydrocarbons. Its advanced manufacturing process safeguards downstream catalysts while targeting a wide array of trace impurities, ensuring optimal performance and longevity. Elevate your purification processes with EA-SRM120, the result of scientific expertise and technological excellence.

Applications:

Olefin purification

Purification of hydrocarbon streams like LPG, Naphtha, etc.

Natural gas and LNG purification

EA-SRM120

EA-SRM120 is a mixed metal oxide sulfur removal adsorbent for unparalleled efficiency in eliminating hydrogen sulfide (H2S), arsine (AsH3), phosphine (PH3), carbonyl sulfide (COS), and mercaptans from liquid and vapor streams. Engineered with precision, EA-SRM120 excels in purifying natural gas, LNG, naphtha, propylene, propane, LPG, and various hydrocarbons. Its advanced manufacturing process safeguards downstream catalysts while targeting a wide array of trace impurities, ensuring optimal performance and longevity. Elevate your purification processes with EA-SRM120, the result of scientific expertise and technological excellence.

Applications:

- Olefin purification

- Purification of hydrocarbon streams like LPG, Naphtha, etc.

- Natural gas and LNG purification