Inert alumina balls, crucial support media for adsorbents and catalysts in reactor vessels, excel in optimizing chemical processes. Composed of over 99% alumina and minimal silica, these balls ensure unparalleled purity and stability. Ideal for high-temperature catalytic reactors such as those in ammonia plants, their low silica content minimizes downstream contamination risks, safeguarding catalyst integrity. Moreover, they prove invaluable in supporting adsorbents for purifying reactive monomers like ethylene and propylene, owing to their remarkable impurity-free nature. With their impeccable composition and functionality, inert alumina balls from Euroadsorbent offer indispensable solutions for enhancing efficiency and reliability in a myriad of industrial applications.

Adapting to the unique specifications of individual units and accommodating customer preferences, we offer flexibility in the supply of this product in various sizes, ranging from 1.6 to 50 mm.

Packing: 220-liter metallic drum, N.W.: 350 -400 kg (other packaging can be supplied on request).

Adapting to the unique specifications of individual units and accommodating customer preferences, we offer flexibility in the supply of this product in various sizes, ranging from 1.6 to 50 mm.

Packing: 220-liter metallic drum, N.W.: 350 -400 kg (other packaging can be supplied on request).

EA-ASB-101

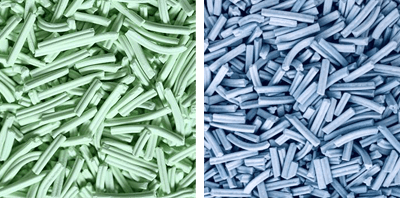

Introducing EA-ASB-101, a cutting-edge inert alumina ball support media engineered for demanding applications in petrochemical and ammonia processing. Comprising over 90% alpha alumina, this product boasts exceptional chemical purity and strength, ensuring unparalleled performance even in extreme environments.

Crafted from meticulously formulated alumina material and fired under stringent conditions, EA-ASB-101 exhibits a flawless spherical shape, guaranteeing optimal contact and distribution. Its high chemical and thermal stability render it impervious to degradation, while its outstanding mechanical and physical properties ensure longevity and reliability.

EA-ASB-101’s low silica composition makes it chemically inert, thwarting catalyst bed fouling and downstream equipment coating.

Applications:

Oil and Gas Refineries

Petrochemicals

Steel and Metal Industry

EA-ASB-101

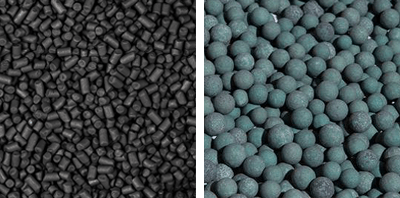

EA-ASB-101is a cutting-edge inert alumina ball support media engineered for demanding applications in petrochemical and ammonia processing. Comprising over 90% alpha alumina, this product boasts exceptional chemical purity and strength, ensuring unparalleled performance even in extreme environments.

Crafted from meticulously formulated alumina material and fired under stringent conditions, EA-ASB-101 exhibits a flawless spherical shape, guaranteeing optimal contact and distribution. Its high chemical and thermal stability render it impervious to degradation, while its outstanding mechanical and physical properties ensure longevity and reliability.

EA-ASB-101’s low silica composition makes it chemically inert, thwarting catalyst bed fouling and downstream equipment coating.

Applications:

- Oil and Gas Refineries

- Petrochemicals

- Steel and Metal Industry

EA-ASB-102

EA-ASB-102, an innovative inert alumina support ball meticulously crafted for demanding industrial applications. Composed of 99+% alpha alumina and minimal SiO2 content, it epitomizes purity and resilience.

Engineered to excel in extreme conditions, EA-ASB-102 is the pinnacle choice for petrochemical and ammonia processing environments. Its superior purity and robustness ensure unparalleled performance in high-temperature and steam-rich settings. By its low silica composition, EA-ASB-102 remains chemically inert, thwarting catalyst bed fouling and downstream equipment coating.

Crafted from a bespoke alumina blend and subjected to stringent firing protocols, EA-ASB-102 boasts flawless spherical geometry, exceptional chemical and thermal stability, and unrivaled mechanical prowess.

Applications:

Oil and Gas Refineries

Petrochemicals

Steel and Metal Industry

EA-ASB-102

EA-ASB-102, an innovative inert alumina support ball meticulously crafted for demanding industrial applications. Composed of 99+% alpha alumina and minimal SiO2 content, it epitomizes purity and resilience.

Engineered to excel in extreme conditions, EA-ASB-102 is the pinnacle choice for petrochemical and ammonia processing environments. Its superior purity and robustness ensure unparalleled performance in high-temperature and steam-rich settings. By its low silica composition, EA-ASB-102 remains chemically inert, thwarting catalyst bed fouling and downstream equipment coating.

Crafted from a bespoke alumina blend and subjected to stringent firing protocols, EA-ASB-102 boasts flawless spherical geometry, exceptional chemical and thermal stability, and unrivaled mechanical prowess.

Applications:

- Oil and Gas Refineries

- Petrochemicals

- Steel and Metal Industry

EA-ASB-103

Step into the future of industrial efficiency with EA-ASB-103, the pinnacle of alumina support ball technology. Engineered with over 99% alpha alumina and minimal SiO2, it’s tailor-made for the toughest environments. From petrochemical to ammonia processing, its high purity and strength ensure reliability under extreme heat and pressure.

With a flawless spherical design and unmatched stability, EA-ASB-103 delivers peak performance. Its advanced formulation and precise manufacturing guarantee superior quality, safeguarding catalyst beds and equipment from wear and tear.

Applications:

Oil and Gas Refineries

Petrochemicals

Steel and Metal Industry

EA-ASB-103

Step into the future of industrial efficiency with EA-ASB-103, the pinnacle of alumina support ball technology. Engineered with over 99% alpha alumina and minimal SiO2, it’s tailor-made for the toughest environments. From petrochemical to ammonia processing, its high purity and strength ensure reliability under extreme heat and pressure.

With a flawless spherical design and unmatched stability, EA-ASB-103 delivers peak performance. Its advanced formulation and precise manufacturing guarantee superior quality, safeguarding catalyst beds and equipment from wear and tear.

Applications:

- Oil and Gas Refineries

- Petrochemicals

- Steel and Metal Industry