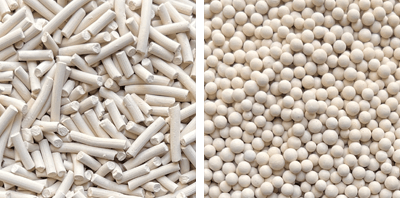

Activated alumina, a highly efficient adsorbent, serves as a crucial protective barrier for gas-phase molecular sieve beds. Renowned for its exceptional volumetric capacity, it adeptly absorbs liquids, preventing detrimental effects such as film coating and accelerated coking induced by hydrocarbon condensates, amine, glycol carryover, and liquid water entrainment.

Its dehydration-grade properties, combined with superior density, enable efficient water removal during non-liquid containment phases, rendering it ideal for thermal swing applications. Minimal impact on regeneration processes, coupled with modest bed height adjustments, underscores its ease of integration. Widely applicable across diverse streams including air, carbon dioxide, sulfur hexafluoride, and various hydrocarbons, it ensures stringent moisture control while maintaining robust thermal and mechanical resilience.

Adapting to the unique specifications of individual units and accommodating customer preferences, we offers flexibility in the supply of this product in various sizes, ranging from 1.6 to 8 mm.

Packing: 220 Lit Metallic Drum – N.W.: 150 kg (other packaging can be supplied on request).

Its dehydration-grade properties, combined with superior density, enable efficient water removal during non-liquid containment phases, rendering it ideal for thermal swing applications. Minimal impact on regeneration processes, coupled with modest bed height adjustments, underscores its ease of integration. Widely applicable across diverse streams including air, carbon dioxide, sulfur hexafluoride, and various hydrocarbons, it ensures stringent moisture control while maintaining robust thermal and mechanical resilience.

Adapting to the unique specifications of individual units and accommodating customer preferences, we offers flexibility in the supply of this product in various sizes, ranging from 1.6 to 8 mm.

Packing: 220 Lit Metallic Drum – N.W.: 150 kg (other packaging can be supplied on request).

EA-A101

EA-A101 is an advanced form of activated alumina meticulously engineered for exceptional performance in adsorption applications within gas and liquid streams. Renowned for its high surface area and porous structure, EA-A101 offers unparalleled capacity for capturing diverse contaminants.

Withstanding rigorous conditions, activated alumina finds utility across a spectrum of industries. From drying air and industrial gases (including hydrogen, oxygen, nitrogen, CO2, and natural gas) to desiccating organic liquids like LPG and hydrocarbon condensate, its robust construction ensures longevity and reliability. Additionally, its high crushing strength and attrition resistance make it an indispensable asset in purifying gases and liquids, proficiently removing metal traces, fluorides, HF, TBC, and HCL.

Applications:

Guard layer for molecular sieve

Natural gas dehydration

Air pre-purification in ASU

PSA / TSA air dryer

Solvent Drying

EA-A101

EA-A101 is an advanced form of activated alumina meticulously engineered for exceptional performance in adsorption applications within gas and liquid streams. Renowned for its high surface area and porous structure, EA-A101 offers unparalleled capacity for capturing diverse contaminants.

Withstanding rigorous conditions, activated alumina finds utility across a spectrum of industries. From drying air and industrial gases (including hydrogen, oxygen, nitrogen, CO2, and natural gas) to desiccating organic liquids like LPG and hydrocarbon condensate, its robust construction ensures longevity and reliability. Additionally, its high crushing strength and attrition resistance make it an indispensable asset in purifying gases and liquids, proficiently removing metal traces, fluorides, HF, TBC, and HCL.

Applications:

- Guard layer for molecular sieve

- Natural gas dehydration

- Air pre-purification in ASU

- PSA / TSA air dryer

- Solvent Drying

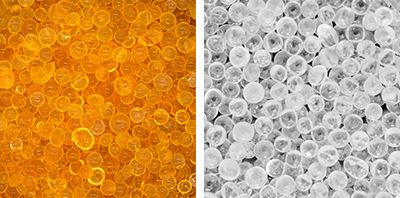

EA-A22

EA-A22 is a modified activated alumina engineered for exceptional adsorption of CO2, H2S, and COS from both vapor and liquid phase process streams. Perfectly suited for diverse applications like hydrogen, olefins, naphtha, and various hydrocarbon streams, its high microporosity ensures rapid diffusion rates, enhancing sulfur and oxygenate contaminants’ adsorption capacity across a broad temperature spectrum.

Unlocking unparalleled advantages, EA-A22 boasts extraordinary adsorption rates, meticulously optimized properties for enduring service, and a wide operating temperature range. Whether purifying gas or liquid feed streams, its effectiveness remains unparalleled.

Applications:

Natural gas/LPG purification

Olefins Purification

PSA Hydrogen purification

EA-A22

EA-A22 is a modified activated alumina engineered for exceptional adsorption of CO2, H2S, and COS from both vapor and liquid phase process streams. Perfectly suited for diverse applications like hydrogen, olefins, naphtha, and various hydrocarbon streams, its high microporosity ensures rapid diffusion rates, enhancing sulfur and oxygenate contaminants’ adsorption capacity across a broad temperature spectrum.

Unlocking unparalleled advantages, EA-A22 boasts extraordinary adsorption rates, meticulously optimized properties for enduring service, and a wide operating temperature range. Whether purifying gas or liquid feed streams, its effectiveness remains unparalleled.

Applications:

- Natural gas/LPG purification

- Olefins Purification

- PSA Hydrogen purification