3A Molecular Sieve, a synthetic A-type zeolite with a potassium-based structure, excels in moisture removal due to its crystalline porous framework with 3 Angstrom pore diameters. It selectively adsorbs water molecules while minimizing the intake of other substances, making it ideal for purification and dehydration in various industries such as petrochemicals, natural gas processing, and air drying applications. Its uniform particle size, high adsorption capacity, and regenerability make it a reliable choice for industrial processes.

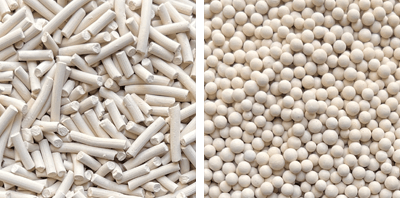

Adapting to the unique specifications of individual units and accommodating customer preferences, we offers flexibility in the supply of this product in various forms, ranging from spherical and pellet to 3A zeolite powder.

Packing: 220 Lit Metallic Drum – N.W.: 140 – 150 kg (other packaging can be supplied according to request).

Adapting to the unique specifications of individual units and accommodating customer preferences, we offers flexibility in the supply of this product in various forms, ranging from spherical and pellet to 3A zeolite powder.

Packing: 220 Lit Metallic Drum – N.W.: 140 – 150 kg (other packaging can be supplied according to request).

EA-Z1003

In addition to possessing an optimal structure conducive to dehydration and facilitating maximum water adsorption, EA-Z1003 exhibits exceptional physical resilience against thermal shocks or compressive stresses. Primarily designated for deployment in natural gas and light hydrocarbon dehydration units, this product ensures sustained operational efficacy owing to its remarkably robust physical attributes. Furthermore, adaptable to diverse process specifications, EA-Z1003 finds utility in the drying of organic solvents or in compressed air dryers operating under temperature swing adsorption (TSA) regeneration mode.

Applications:

Natural Gas Dehydration

Solvent Drying

Air Dehydration

EA-Z1003

In addition to possessing an optimal structure conducive to dehydration and facilitating maximum water adsorption, EA-Z1003 exhibits exceptional physical resilience against thermal shocks or compressive stresses. Primarily designated for deployment in natural gas and light hydrocarbon dehydration units, this product ensures sustained operational efficacy owing to its remarkably robust physical attributes. Furthermore, adaptable to diverse process specifications, EA-Z1003 finds utility in the drying of organic solvents or in compressed air dryers operating under temperature swing adsorption (TSA) regeneration mode.

Applications:

- Natural Gas Dehydration

- Solvent Drying

- Air Dehydration

EA-Z1003-OP

This specialized grade of 3A molecular sieve is meticulously designed to minimize co-adsorption, specifically targeting applications in reactive feeds such as cracked gas or olefin streams. The optimization of pore diameter ensures minimal uptake of unsaturated hydrocarbons like ethylene, thereby preempting process issues and enhancing the stability of purification units.

Furthermore, owing to its remarkable selectivity, this product proves adept at separating water and ethanol to attain purities surpassing the azeotropic point of alcohol. With the integration of suitable regeneration systems, it offers the tantalizing prospect of continuous production of pure alcohol.

Applications:

Cracked Gas Dehydration

Olefin Dehydration

Solvent Drying

Ethanol Dehydration

EA-Z1003-OP

This specialized grade of 3A molecular sieve is meticulously designed to minimize co-adsorption, specifically targeting applications in reactive feeds such as cracked gas or olefin streams. The optimization of pore diameter ensures minimal uptake of unsaturated hydrocarbons like ethylene, thereby preempting process issues and enhancing the stability of purification units.

Furthermore, owing to its remarkable selectivity, this product proves adept at separating water and ethanol to attain purities surpassing the azeotropic point of alcohol. With the integration of suitable regeneration systems, it offers the tantalizing prospect of continuous production of pure alcohol.

Applications:

- Cracked Gas Dehydration

- Olefin Dehydration

- Solvent Drying

- Ethanol Dehydration